Forklift Safety Signs-- Required Safety Signs for Every Storehouse

Forklift Safety Signs-- Required Safety Signs for Every Storehouse

Blog Article

Secret Considerations for Designing Effective Forklift Safety Signs

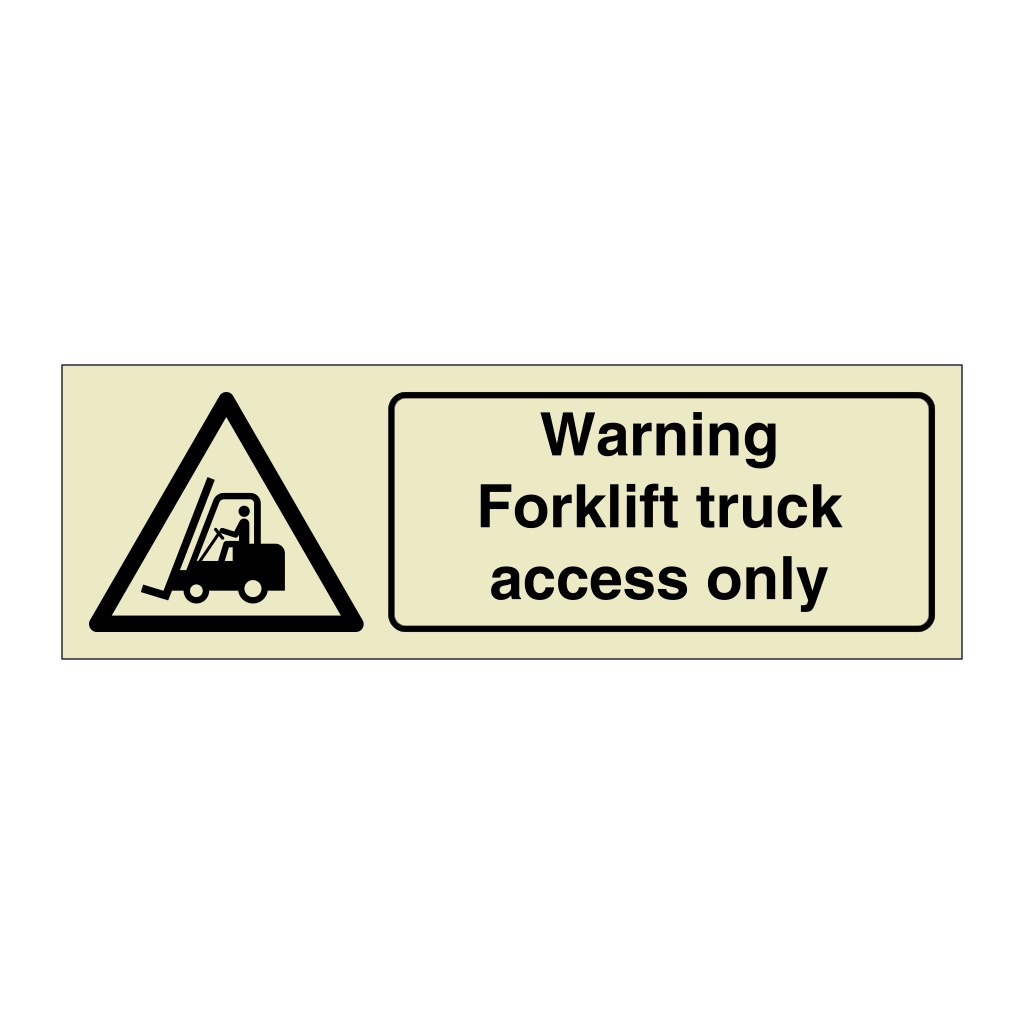

When creating reliable forklift safety and security indicators, it is critical to take into consideration a number of essential aspects that jointly make sure ideal visibility and quality. High-contrast colors matched with large, readable sans-serif fonts dramatically enhance readability, especially in high-traffic locations where quick understanding is important. forklift signs. Strategic placement at eye level and using durable products like aluminum or polycarbonate additional add to the durability and performance of these signs. In addition, adherence to OSHA and ANSI standards not only standardizes safety messages but additionally bolsters compliance. To totally grasp the complexities and finest practices included, numerous added factors to consider advantage closer interest.

Shade and Contrast

While developing forklift safety and security indications, the choice of shade and comparison is vital to guaranteeing presence and efficiency. The Occupational Security and Wellness Management (OSHA) and the American National Criteria Institute (ANSI) give standards for using shades in security indications to standardize their definitions.

Reliable contrast in between the history and the message or symbols on the indicator is equally crucial (forklift signs). High contrast makes certain that the indication is readable from a range and in differing lighting conditions.

Using ideal color and comparison not only sticks to governing standards however likewise plays a crucial duty in maintaining a secure working atmosphere by ensuring clear communication of threats and instructions.

Font Style Size and Design

When designing forklift safety indicators, the option of typeface dimension and design is crucial for ensuring that the messages are clear and promptly recognized. The main goal is to improve readability, specifically in environments where quick details processing is important. The font style dimension ought to be big sufficient to be checked out from a distance, accommodating varying view conditions and making certain that employees can comprehend the indicator without unnecessary stress.

A sans-serif font is commonly advised for safety indications due to its clean and straightforward look, which improves readability. Font styles such as Arial, Helvetica, or Verdana are usually favored as they lack the detailed details that can obscure crucial information. Uniformity in font style throughout all safety signs aids in creating an attire and specialist appearance, which additionally reinforces the relevance of the messages being conveyed.

Furthermore, focus can be achieved through strategic use of bolding and capitalization. By very carefully picking appropriate font style dimensions and styles, forklift safety and security indications can efficiently connect vital safety information to all personnel.

Positioning and Exposure

Making sure ideal positioning and presence of forklift safety and security signs is vital in industrial settings. Proper sign positioning can substantially reduce the threat of mishaps and improve overall workplace security. Signs must be positioned at eye degree to guarantee they are quickly visible by operators and pedestrians. This usually indicates putting them between 4 and 6 feet from the ground, depending upon the ordinary height of the workforce.

Signs need to be well-lit or made from reflective materials in poorly lit areas to guarantee they are noticeable at all times. By thoroughly thinking about these facets, one can make sure that forklift safety indicators are both reliable and visible, thereby fostering a much safer working setting.

Material and Sturdiness

Choosing the appropriate products for forklift safety signs is important to ensuring their longevity and efficiency in industrial atmospheres. Provided the severe problems typically run into in storehouses and making centers, the products selected have to stand up to a variety of stressors, including temperature variations, dampness, chemical exposure, and physical influences. Sturdy substrates such as light weight aluminum, high-density polyethylene (HDPE), and polycarbonate are check this popular options due to their resistance to these components.

Light weight aluminum is renowned for its effectiveness and rust resistance, making it an outstanding option for both indoor and exterior applications. HDPE, on the other hand, supplies phenomenal impact resistance and can withstand prolonged exposure to severe chemicals without degrading. Polycarbonate, recognized for its high influence stamina and clearness, is usually click to read more used where visibility and resilience are vital.

Just as crucial is the sort of printing made use of on the signs. UV-resistant inks and protective coatings can significantly boost the life-span of the signs by preventing fading and wear triggered by extended direct exposure to sunlight and other environmental elements. Laminated or screen-printed surface areas offer extra layers of protection, making certain that the critical safety and security information remains clear with time.

Purchasing high-quality products and durable manufacturing processes not just expands the life of forklift safety indicators yet likewise strengthens a culture of safety and security within the workplace.

Conformity With Regulations

Complying with regulative criteria is vital in the style and implementation of forklift security indicators. Compliance ensures that the indications are not just effective in communicating critical security details yet also fulfill lawful responsibilities, therefore reducing potential liabilities. Various organizations, such as the Occupational Safety and Health And Wellness Management (OSHA) in the United States, offer clear guidelines on the specifications of safety indicators, including color design, message size, and the incorporation of globally recognized signs.

To conform with these guidelines, it is important to carry out a comprehensive review of applicable requirements. For example, OSHA mandates that safety indications must be visible from a range and include certain colors: red for risk, yellow for care, and green for security directions. Furthermore, sticking to the American National Criteria Institute (ANSI) Z535 series can even this hyperlink more boost the efficiency of the indications by standardizing the layout elements.

Moreover, regular audits and updates of security indicators should be performed to make certain recurring conformity with any changes in policies. Involving with accredited safety specialists throughout the style stage can likewise be valuable in ensuring that all regulatory demands are fulfilled, and that the signs offer their designated purpose properly.

Verdict

Designing reliable forklift safety signs calls for careful focus to color comparison, typeface size, and design to guarantee optimum presence and readability. Adherence to OSHA and ANSI standards systematizes security messages, and integrating reflective materials boosts visibility in low-light circumstances.

Report this page